Blog Post

Tips for Preventing Hydraulic Fitting Leaks

- By Admin

- •

- 20 Feb, 2019

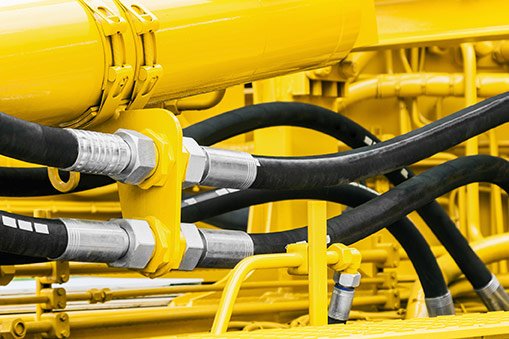

Your hydraulic fittings are likely very small. And because they are so small, many people believe that they are not very important. However, nothing could be further from the truth.

In fact, if you have the wrong fitting, or if a fitting that has an issue, your system can easily develop leaks and other issues. Fortunately, you have many options for keeping leaks from happening and keeping your fittings in perfect working order. Follow these tips to avoid fitting leaks.

Use Only Compatible Couplings

Dozens of different types of hydraulic couplings are available. To make things even more complicated, each manufacturer typically makes one or more types of each specific coupling.

With so many coupling options available, knowing which couplings are right for your specific hose can be difficult.

However, you need to make absolutely certain that you are using only couplings that are compatible with your hose. Ideally, you will want to use items from the same brand or product line. Even if you don't do that, make sure that the coupling is approved for use with your specific hose. Not doing so could easily lead to leaks or other issues.

Never force a coupling to go on your hose either. If it isn't fitting correctly, the coupling isn’t correct for the fitting. And even if you can get an incorrect coupling to fit by forcing it into place, you're just asking for trouble.

Eliminate Joint and Thread Connections Where You Can

The fewer connective parts you have, the lower the risk of developing a fitting leak.

Thus, when designing systems, you should cut out any and all thread and joint connections that you can. Even after you have designed your system, you may be able to go back through and restructure somewhat to eliminate any extraneous or unnecessary connections.

The fewer connections you have, the less upkeep and vigilance are required, making for a more effective and easier-to-manage system overall.

Choose Superior, High-Quality Connectors

In addition to ensuring that you choose connectors and fittings designed to work specifically with your system, also make sure you choose high quality, well-made fittings.

Ideally, you want fittings that have an elastomeric seal. This seal, which can be made from a range of materials and comes in a variety of styles, can really help when it comes to keeping leaks from happening.

Tighten Fittings Regularly

Even if you choose the most perfect hydraulic fittings possible, you still need to do some maintenance or upkeep yourself to keep them working properly.

One of the most important things you can do is to regularly tighten these fittings. Even the best fittings will often grow looser with wear, making room for leaks and other problems.

How often you will need to tighten your fittings will depend on a variety of factors, such as the age of the fittings, the frequency of use, and more. However, with help from a professional service, you can get set up on a regular maintenance schedule that will keep your fittings tight, leak-free, and in tip-top shape.

Reduce Vibration where Possible

Finally, whenever possible, do everything you can to reduce vibration within your system, especially in areas where fittings are present.

Too much vibration can lead to loosening of your fittings, which can, in turn, lead to leaks. If you can't stop vibration fully, add in support and reinforcement for your fittings. This will help to reduce the likelihood of leaks by reducing the impact of vibration.

If you can follow these tips and seek help from a professional service, such as Kims International, worries about leaks should quickly become a thing of the past. Contact Kims International today.

Share

Tweet

Share

Mail

KIMS International

11516 E 58th St.

Tulsa, OK 74146

Phone:

918-250-9441

After Hours Phone: 918-906-5371

Fax:918-252-5742

Sales : [email protected]

Accounting : [email protected]

Business Hours

- Mon - Fri

- -

- Saturday

- -

- Sunday

- Closed

24-Hour On-Call Service

Call After Hours: 918-906-5371

Share

Tweet

Share

Mail

Accounts Available

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy